Seto Shuzo

The hometown of Azumacho, located in Shioda Town, Ureshino City, Saga Prefecture, lies upstream of the Shioda River, which flows into the Ariake Sea to the west of the Saga Plain. This quiet rural town is abundantly blessed with high-quality rice, clear inland air, and pure water, all of which are essential for sake brewing. Established in 1789, Azumacho has been enjoyed by the local people for over 200 years. Seto Shuzo Co., Ltd. "Azumacho" was founded by the first-generation master, Tajihei Seto, in Shioda Town, Ureshino City, Saga Prefecture, under the brand name "Maruhei Masamune." In 1920, the company became a corporation and launched the "Azumacho" brand. The name was given by then Prime Minister and Seiyukai leader, Hara Takashi, who praised the sake’s refreshing aftertaste and generous character, likening it to "the king of the East, the ruler of Azuma," hence the name "Azumacho." In 1926, it was chosen as a representative product by the Imperial Household and was supplied to the Imperial Family. During the pre-war period, it became an official product of the Imperial Household Agency, and in November 1945, it was designated by the GHQ and won the admiration of General MacArthur. The brand has also earned numerous prestigious awards, including the Gold Medal at the National New Sake Evaluation and the Fukuoka National Tax Office Evaluation, continuing to receive honor and recognition to this day.

Sake Brewing Concept

Since its founding, our mission has been to "create honest sake." This commitment has been passed down unchanged through the years. With patience, care, and dedication, we continue to preserve and follow the time-honored, luxurious traditional brewing methods, crafting authentic Japanese sake. Our founding wish to "create honest sake" has remained steadfast, with genuine sake being brewed slowly and thoughtfully, year after year.

Rice Varieties

At our company, we are committed to using only locally grown rice from Saga Prefecture, including varieties such as Yamada Nishiki, Saga no Hana, and Reihou. Yamada Nishiki, in particular, is cultivated in our own fields by our employees (brewery workers), and we also use sake rice grown in partnership with contracted farmers, where both our employees and the farmers work together to produce the rice. This dedication ensures the highest quality ingredients and supports local agriculture.

Rice polishing

The process of milling rice to remove the germ and outer layers, including proteins and fats, is known as seimai (polishing). At our company, we use an original temperature and moisture control milling machine for all the sake rice we use. This allows us to achieve high levels of rice polishing while maintaining the rice's integrity and reducing breakage, even at high polishing rates.

Original Temperature and Moisture Control Milling Machine: During the high-polish milling process, rice often becomes too hot, causing the moisture to evaporate, which can lead to the rice breaking. This is known as ineffective polishing. For example, even if the rice is polished to 50%, if there is 10% ineffective polishing, the actual polishing rate would be 60%. This true polishing rate is referred to as the true polishing ratio (shin seimai-bōhō). The original temperature and moisture control milling machine ensures that the true polishing ratio is as close as possible to the labeled polishing ratio, maintaining the rice's quality while achieving optimal polishing.

Washing and Soaking Rice

Ultrasonic Rice Washing

After the rice is polished, the surface of the white rice still contains some bran that needs to be removed. To do this, we wash the rice with water and soak it to allow the grains to absorb moisture.

At our company, we use an ultrasonic washing machine, where the rice is quickly submerged in water, and small bubbles are generated through ultrasonic waves. The rice is then washed by the flow of water, effectively removing any residual bran. Once the washing process is complete, we drain the water quickly, leaving the rice with just the right amount of moisture for soaking. This results in perfectly soaked rice, ready for the next stage of brewing.

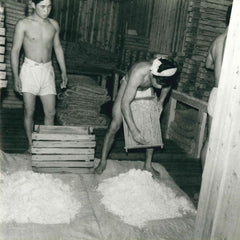

Steaming Rice

Through the washing and soaking process, the rice is carefully infused with the right amount of moisture to create soaked rice, which is then gently and meticulously steamed. The result is ideal steamed rice, known as "outer hard, inner soft" (外硬内軟), where the outer layer is firm and the inside is soft, ensuring the perfect texture for fermentation.

Once the rice has been steamed to perfection, it is cooled down to the appropriate temperature for the brewing process, ensuring that it is ready for the next steps in creating high-quality sake. This careful attention to detail in steaming plays a crucial role in achieving the ideal texture and flavor profile of the sake.

Koji (麹)

Koji making is considered one of the most crucial steps in sake brewing, often described by the saying, "One koji, two yeast starter, three brewing" (一麹二酛三造り). There are two main types of koji used in sake production: "motokoji" (used for creating the yeast starter or "shubo") and "kakekoji" (used in the fermentation process when preparing the mash). Each type of koji requires specific care and conditions to be made successfully.

The steamed rice, cooled to the right temperature, is placed into the koji room (kojimuro) at a constant 30°C. The koji mold is evenly spread over the rice, and for about 48 hours, the mold is carefully cultivated to grow uniformly.

At our company, we maintain strict temperature control, adjusting it in 0.1°C increments, to produce koji tailored to various types of sake and brewing purposes, ensuring high-quality production.

In addition to temperature management, hygiene plays a crucial role in the successful growth of the koji mold. We focus on daily cleaning of all equipment and emphasize proper hand washing to maintain an environment that ensures the pure cultivation of the mold. This meticulous attention to both temperature and cleanliness results in premium koji that enhances the overall quality of our sake.

Yeast Starter (Shubo, 酒母)

Sake is made by fermenting steamed rice, koji, and water. During fermentation, the koji breaks down the starch in the steamed rice into sugars, which the yeast then consumes, producing alcohol and carbon dioxide. For this process, a large quantity of high-quality yeast is required, which is why a yeast starter, known as shubo (酒母), is created to propagate the yeast.

In about 12 days, a large amount of healthy yeast is cultivated in the shubo, which is then ready for use in the main fermentation process. At our company, all of our shubo is produced using the sokujomoto (速醸酛) method, a rapid yeast starter method. This technique ensures the consistent and efficient growth of yeast, which is essential for creating high-quality sake with a clean and refined flavor profile.

Preparation

Once the yeast starter (shubo) is ready, the brewing process begins. Traditionally, sake is brewed using a three-stage fermentation process, known as "sandan shikomi" (三段仕込み), where steamed rice and koji are added in three stages: "so" (添), "naka" (仲), and "shiro" (留). However, the four-stage brewing method has become more common today.

The four-stage brewing method involves the addition of a fourth stage after the three traditional stages. In this process, rice bran saccharification devices or enzymes are used to artificially create sugars, which are then added to the mash during pressing to create a high-alcohol raw sake (genshu) in large quantities.

At our company, we refrain from using any artificial sweeteners such as rice bran saccharification devices or enzymes. Instead, we continue to produce all of our sake, from Daiginjo to Honjozo, using the traditional three-stage brewing method, ensuring the authentic and natural creation of our sake.

Analysis

Once the brewing process is complete, the management of the fermentation mash (moromi) involves key tasks such as stirring (kaiire), temperature checks (kentou), and analysis.

Stirring (Kaiire)

The purpose of stirring the moromi is twofold: to mix the ingredients and ensure even temperature distribution, and to release carbon dioxide from the mash to promote fermentation. Stirring helps in maintaining a uniform temperature throughout the mash, ensuring a consistent fermentation environment.

Analysis

During the morning stirring session, a small sample of the moromi is taken to measure its alcohol content, sake meter value (nihonshudo), acidity, and amino acid levels. Based on these measurements, the appropriate temperature for the moromi is determined. At Seto Shuzo, we take temperature control very seriously, managing the moromi's temperature with precision to 0.1°C increments, ensuring optimal conditions for fermentation and the production of high-quality sake.

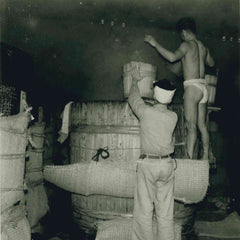

Pressing (Jōsō, 上槽)

After fermentation is complete, the moromi is separated into sake and sake lees (kasu). This process is called jōsō (上槽) or pressing. At our company, we do not use artificial enzymes or rice bran saccharification devices. We only use the traditional three-stage brewing method, even for producing sweet sake. As a result, even for Honjozo, we maintain a kasu ratio of over 40%, the same as Daiginjo.

The kasu ratio refers to the proportion of sake lees. For example, with a 30% kasu ratio, from 100kg of polished rice, 30kg will become sake lees, and the remaining 70kg will be turned into sake.

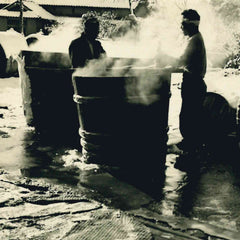

Filtration and Maturation (Roka & Jukusei, 濾過・熟成)

After pressing, the sake undergoes filtration (ろか, roka). Even after the sake is clarified, residual enzymes from the koji and yeast remain, and if left untreated, the sake's flavor will continue to change over time. To prevent this, the sake is heated to 65°C to deactivate the yeast and enzymes, stabilizing the sake's quality. This process is known as "hiire" (火入れ, pasteurization). Once the pasteurization is complete, the sake is allowed to mature in the brewery for approximately six months.

Bottling (Binzume, 瓶詰め)

The sake that has matured for six months in the brewery is bottled and awaits shipment.

The sake named by Hara Takashi and loved by MacArthur.

Hara Takashi

The 19th Prime Minister

The Prime Minister Who Named "Azumacho"

The sake brand Azumacho was named by Prime Minister Hara Takashi. After the downfall of the Terauchi Masatake Cabinet during the Rice Riots, Hara Takashi, leader of the Rikken Seiyūkai party, formed a new cabinet in 1918 and focused on international diplomacy. He signed the Treaty of Versailles, joined the League of Nations, and participated in the Washington Conference, fostering cooperation with the United States.

The head of Seto Shuzo, a Seiyukai party member, had ties to Prime Minister Hara. In 1920, during a naval exercise in Nagasaki, Hara was asked to suggest a new name for the sake brewery, which had been producing sake under the name "Maruhei Masamune." Hara praised the sake’s refreshing taste and generosity, calling it "fitting for the ruler of Azuma, the king of the East," and gave it the name Azumacho. Since then, Seto Shuzo has continued to brew under this name, striving to live up to its legacy.

Douglas MacArthur

Commander in Chief of GHQ

The Sake of Peace Loved by the General

The sake that was loved by General MacArthur, known as the "Sake of Peace." In 1945, during the chaotic post-war period in Japan, a party hosted by the GHQ (General Headquarters) was held, and the 12th-generation potter from Arita, Sakai-ya Kakemon, was invited. At the time, Tokyo was far away, and information was scarce, so Kakemon, unsure of the situation, visited his close friend, Heihachi Seto. They drank together that night, thinking it might be their last drink. The next morning, Kakemon took a bottle of Azumacho with him for the journey. Unfinished on the train, he brought the sake to the GHQ party, where it caught the attention of General MacArthur.

Impressed by the sake, Azumacho became a designated product of the GHQ. Post-war, it became a symbol of peace between Japan and the United States. The sake that captivated General MacArthur continues to be loved by many to this day.

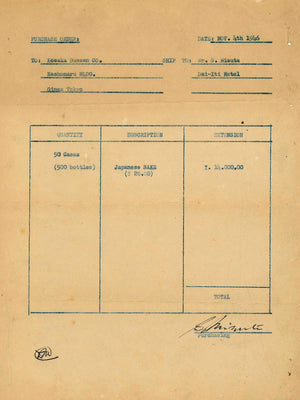

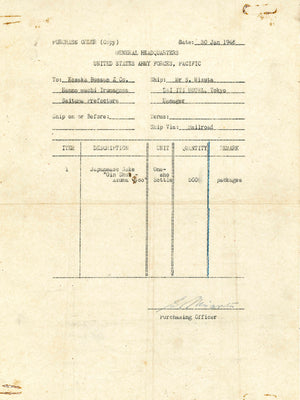

The Order Forms from the GHQ and General MacArthur Still Kept in the Brewery

Purchase Order from MacArthur

Purchase Order from GHQ

Difference in Sake Yield Between Azumacho and the National Average

National Average Value: Extracted from the 2013 Sake Production Report (Preliminary Data)

| Brand | Class of sake | Lees ratio (%) | Alcohol content rate | Alcohol content of raw liquor | Unpasteurized sake meter value |

|---|---|---|---|---|---|

| Daiginjo Azumacho | Daiginjo | 40.4 | 322.7 | 18.1 | +3.9 |

| National average | Ginjo | 36.5 | 355.0 | 18.8 | +3.8 |

| Houmon Azumacho |

Junmai ginjo | 40.4 | 334.6 | 17.2 | -6.6 |

| National average | Junmai ginjo | 35.9 | 368.0 | 17.5 | +1.7 |

| Keimon Azumacho | Tokubetsu Junmai | 41.9 | 329.0 | 17.5 | -6.4 |

| National average | Junmai | 28.3 | 383.0 | 18.1 | +1.5 |

| Junmai Azumacho | Junmai | 31.0 | 358.0 | 17.8 | -4.6 |

| National average | Junmai | 28.3 | 383.0 | 18.1 | +1.5 |

| Tokusen Azumacho | Honjozo | 48.6 | 268.3 | 18.0 | -12.0 |

| National average | Honjozo | 28.7 | 369.0 | 19.7 | +3.4 |

| Kinmon Azumacho | Honjozo | 45.0 | 281.9 | 18.4 | -11.0 |

| National average | Honjozo | 28.7 | 369.0 | 19.7 | +3.4 |

| Maruhei Azumacho | Honjozo | 45.0 | 287.4 | 18.5 | -7.4 |

| National average | Honjozo | 28.7 | 369.0 | 19.7 | +3.4 |

Kasu Ratio (粕歩合): The kasu ratio refers to the weight ratio of sake lees (kasu) to the rice used as raw material. For example, a kasu ratio of 30% means that from 100kg of polished rice, 30kg will become sake lees, and the remaining 70kg will become sake. A higher kasu ratio indicates a more luxurious sake.

Sake Yield Ratio (酒化率, Raw Material Utilization Rate): This refers to the amount of pure alcohol obtained per ton of polished rice. Generally, for high-quality sake such as ginjo sake, the sake yield ratio is lower, indicating more efficient use of the raw materials to produce a high-quality product.

Seto Shuzo Co., Ltd.

3117 Gochodaka, Shiotamachi, Ureshino City, Saga Prefecture 849-1425, Japan

Phone: 0954-66-2014

Email: info@azumacho.co.jp

President: Heiji Seto

Company Established: October 28, 1920 (Taisho 9)

Founded: 1789 (Kansei 1)

Business Hours: Monday to Friday: 8:00 AM - 5:00 PM

Closed: Saturday, Sunday, and Public Holidays

Water Source

Taradake mountain range

The brewing water, which can be said to be the lifeblood of Seto Sake Brewery's sake brewing, is clear underground water from the Taradake mountain range, known as one of Japan's leading water sources. This water has been refined over many years by the rich natural environment, making it "slightly soft water" that is ideal for sake brewing. It contains very few impurities and only a small amount of iron and other components that affect the quality of the sake, so it brings out the maximum flavor of the rice and promotes gentle, healthy fermentation by the yeast.

The result is a delicate sake with a fine texture, a soft mouthfeel, and a rich aroma. The high quality of the water has been historically valued, so much so that there is a legend that Kobo Daishi Kukai was so moved by the purity of the water here that he built a temple here. This legend symbolizes the purity and outstanding quality of Mt. Taradake's water. At Setagaya Sake Brewery, we carefully use this precious water, blessed by nature and with a historical background, as the core of our sake brewing, elevating it to a transparent sake with a deep flavor.

Rice producing area

On the Premises of Seto Shuzo

Seto Shuzo takes great pride in its Yamada Nishiki rice, which is astonishingly cultivated right on the brewery's premises. This reflects the brewery's philosophy that "the best sake comes from the best rice, and rice cultivation is the first step in sake brewing." Grown with love and care by the brewery workers, this Yamada Nishiki flourishes in the rich soil of Ureshino City, Shiotamachi, sharing the same water vein as the pure underground spring water from the Tara Mountain Range, which is used in brewing.

Harvested and immediately used for brewing, this rice boasts exceptional purity and embodies the unique characteristics of the land. The Yamada Nishiki cultivated on the brewery grounds is the ultimate source that creates delicate and richly aromatic sake, vividly reflecting the terroir of Seto Shuzo.